Quality

Our Advance Quality Testing Machinery

Tensile Tester

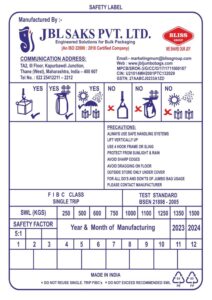

Quality : A Tensile Tester can test the strength and durability of your FIBC bags, ensuring that they meet your quality standards and customer expectations. This can help you avoid costly product recalls and improve your brand reputation.

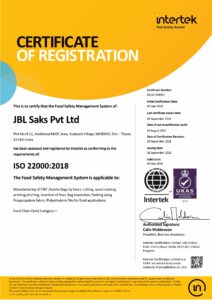

Compliance: A Tensile Tester can help you comply with industry standards and regulations for FIBC bags, such as ISO, ASTM, and EN. By ensuring that your products meet these standards, you can avoid legal issues and penalties.

Efficiency: A Tensile Tester can perform tests quickly and accurately, reducing the amount of time and labor required for quality control. This can increase your productivity and reduce your operational costs.

UV Tester

Quality control: A UV Tester can test the resistance of your FIBC bags to UV radiation, ensuring that they maintain their strength and durability when exposed to sunlight. This can help you avoid product failures and increase customer satisfaction.

Compliance: A UV Tester can help you comply with industry standards and regulations for FIBC bags, such as ISO, ASTM, and EN. By ensuring that your products meet these standards, you can avoid legal issues and penalties.

Cost savings: By testing the UV resistance of your FIBC bags, you can identify materials and designs that are more resistant to UV radiation, reducing the need for frequent replacements and repairs. This can help you save costs and increase your profitability.

Test Rig

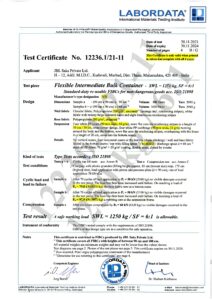

Quality control: A test rig can simulate real-world conditions and test the strength and durability of your FIBC bags, ensuring that they meet your quality standards and customer expectations. This can help you avoid costly product failures and recalls.

Product development: A test rig can also help you develop new products and improve existing ones by providing data on the performance of different materials and designs under various conditions. This can help you innovate and stay ahead of your competitors.

Compliance: A test rig can help you comply with industry standards and regulations for FIBC bags, such as ISO, ASTM, and EN. By ensuring that your products meet these standards, you can avoid legal issues and penalties.