Infrastructure

Our Advance Machinery

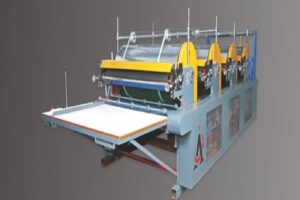

Auto Cutting Machine

Auto Cutting Machine in our plant provides great advantages like Efficiency & Productivity.

Increased efficiency and productivity: With an Auto cutting machine, we can cut your FIBC bag fabric quickly and accurately. This saves time and reduces labor costs, allowing us to increase your production output and meet customer demand more efficiently.

Improved accuracy and consistency: The computerized control system in the Auto cutting machine ensures that each cut is precise and consistent, reducing the risk of errors and waste. This helps us to produce high-quality FIBC bags consistently, which can enhance your brand reputation and customer satisfaction.

Baling Machine

Baling machine offers several advantages that positively impacts our production process and product quality..

Improved efficiency: With a baling machine, we can compress your FIBC bags quickly and efficiently, reducing the amount of time and labor required for handling and transport. This can increases our productivity and helps us to deliver the product in required timeframe.

Baling machine in our manufacturing plant offers several advantages, including space optimization, improved efficiency, reduced waste, enhanced safety, and cost savings.

Circular Loom

Circular loom offers several advantages that positively impacts our production process and overall product quality.

High production capacity: Circular looms can weave large quantities of fabric at high speeds, allowing you to produce FIBC bags in bulk and meet customer demand quickly and efficiently.

Consistent quality: Circular looms are designed to produce uniform fabric with consistent quality, reducing the risk of defects and ensuring that your FIBC bags meet your customers' expectations.

Flexibility and customization: Circular looms can be adjusted to produce fabric of different sizes, colors, and patterns, enabling you to produce a wide range of FIBC bags according to your customer's requirements.

Cost savings: By producing your own fabric using a circular loom, you can reduce your production costs and increase your profitability. You can also reduce your dependence on external suppliers and improve your supply chain management.

Reduced environmental impact: By producing your own fabric using a circular loom, you can reduce your carbon footprint and environmental impact. Circular looms consume less energy and produce less waste compared to other weaving technologies.